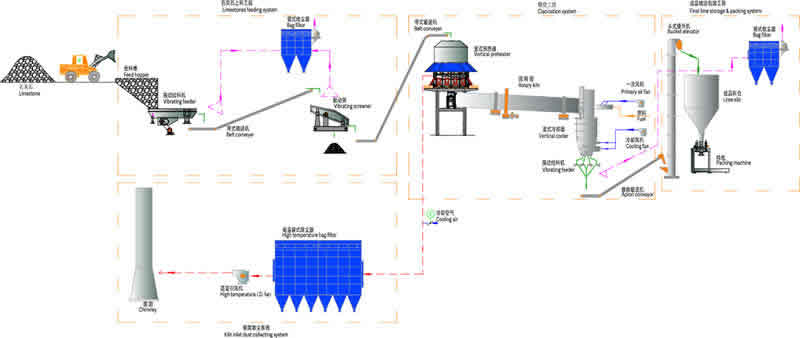

Equipments: crusher, dryer, rotary kiln, vertical cooler, dust collector, hoist, conveyor, etc.

Processing material: limestone particles with a particle size of 10-40mm

Production capacity: 50-800 TPD

Email: sale@turuimac.com

Email: sale@turuimac.com

Lime can be divided into two types: ordinary lime and active lime. Ordinary lime is mostly burned in earth kilns and ordinary vertical kilns, and its activity is generally within 200ml, which is mainly used for construction and road; active lime is mainly made by mechanical vertical kiln and rotary Kiln firing, its activity can reach 300~420ml. The limes burned in rotary kilns have good quality and they are mainly used in industries such as steel smelting, chemical industry and power plant desulfurization. Among all the active lime production processes, the most commonly used is rotary kiln production process. The main feature of this process is that it combines the advantages of good preheating effect of the shaft kiln, low heat consumption, and high uniformity of the temperature field of the rotary kiln. A rotary kiln with a vertical preheater and a vertical cooler is used to calcinate limestone, which meets the production requirements of energy saving, environmental protection and good activity.

1. High level of automation: The production line is equipped with temperature and pressure monitoring instruments, and the operating parameters are displayed by computer. The production line can adopt advanced computer control methods to realize the automation of the entire system.

2. A variety of fuel selection: The fuel can be producer gas, natural gas, coal bed methane and pulverized coal.

3. Advanced technology: Limestone calcination is composed of vertical preheater + rotary kiln + vertical cooler, which meets the production requirements of energy saving, environmental protection and good activity.

The process mainly includes raw material storage and transportation, limestone calcination, final product delivery, Flue gas treatment

Limestone with a particle size of 10-50mm is transported to the factory area and stacked in the stockyard. Loaders are used for stockyard operations. The material with qualified particle size is loaded into the receiving trough set in the material yard by the loader, and under the receiving trough is quantitatively fed by the feeder, the stone is fed to the large inclination conveyor, and then sent to the screening building, where the limestone is screened After being divided, the qualified particle size is weighed and sent to the silo on the top of the preheater by a large inclination conveyor. The powder under the sieve is sent to the storage yard by the 3# conveyor and is regularly transported out by a forklift.

Limestone calcination is composed of a vertical preheater + a rotary kiln + a vertical cooler, with an output of 100-800t/d. The material is introduced into the preheater body from the silo on the top of the preheater through the discharge chute, and at the same time by the rotary kiln The incoming high-temperature flue gas preheats the material to above 1000°C to partially decompose the limestone, and then pushes it into the tail of the rotary kiln by a hydraulic push rod in turn, after being calcined at a high temperature in the rotary kiln, it is discharged into the cooler and blown in by a fan Cooling by the cold air, the material is cooled to ambient temperature +60℃ or lower and discharged from the cooler. The air blown in by the cooler enters the rotary kiln as secondary air to participate in combustion.

After being discharged from the cooler, the finished lime is transported to each finished lime storage by chain conveyor, bucket elevator and belt conveyor. The discharge valve under the lime storage silo is used to load the lime in the silo into cars and tankers for transportation. Set up storage warehouses of different sizes according to customer requirements.

The finished product silo adopts circular silo, 2 5~50mm finished product silo, 1 finished product silo less than 5mm, the volume of each silo is about 800t.

The high-temperature flue gas generated by the combustion of the rotary kiln is exchanged with limestone in the preheater, and the temperature is reduced to below 250 ℃, and then enters the cyclone dust collector for primary dust collection to collect large particles of dust, and then It enters the bag filter and is discharged into the atmosphere by a high-temperature fan after dust removal. The dust concentration of the exhaust gas is less than 30mg/m3. A cold air control system is installed at the inlet of the dust collector to protect the dust collector.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

Advantages of Production Line

Full and complete service system, professional team, guarantee the production efficiency

Specific solutions for you to meet small, medium and large sized production needs

Product installation,commissioning, technical training, etc

Please feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.