Capacity: 0.58-135.4M3

Feeding Size: <3mm

Application: beneficiation, batching and mixing

Materials: gold ore, copper ore, iron ore, manganese ore

copper ore

gold ores

iron ores

manganese ore

Applied material:

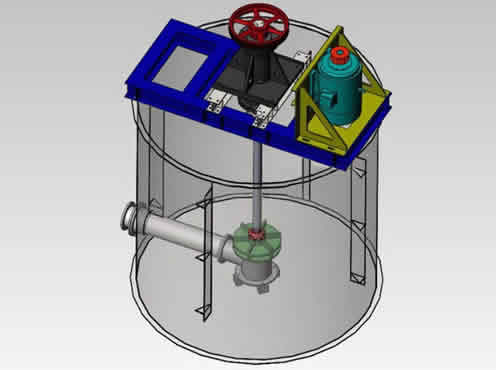

The mixing tank is driven by the motor V-belt to drive the impeller to rotate, fully mix the medicine and the pulp evenly, increase the reaction time of the medicine, and strengthen the quality of the medicine reaction.

Instructions for the use of the mixing tank: Before use, tighten the bolts of the pump body, turn the pump shaft wheel to see if it is flexible, and then start up and run, and the others are the same as the flotation machine.

Wearing parts: impeller, stator.

This machine is suitable for beneficiation and mining, and can also be used for mixing ingredients in various chemical industries.

The machine is set before the flotation operation to fully mix and contact the agent with the pulp, so as to maximize the effect of the agent. It is suitable for the stirring of pulp and flotation reagent whose concentration is not more than 30% and ore density is not more than 3.5.

1. Good sealing performance

Due to the compact structure of the equipment, the internal structure gap is too small, and the dust is not easy to enter during work, and a dust baffle is installed at the feeding port of the equipment to prevent the reverse string of water mist and effectively prevent the entry of sundries and dust.

2. Well mixing

The structure design is reasonable, the stirring blade of the mixing tank is designed as a fan, and the contact area with the medium is large during operation, so as to achieve the effect of uniform stirring of the material.

3. Easy to adjust

The nozzles of the mixing tank have multi-row settings, and the water volume is uniform and adjustable, which is convenient and time-saving.

4. Advanced Components

The mixing tank is composed of advanced technology and structure, so that the whole machine has the characteristics of advanced equipment performance, stable product quality, uniform mixing, and rapid discharge.

The mixing tank is composed of electric motor, impeller, stator, bearing and other components, and adopts the mechanical stirring method of flat-bottomed barrel-shaped radial circulation spiral impeller to carry out the stirring operation.

When the mixing tank is working, the motor pulls the V-belt to drive the impeller to rotate, and the pulp and the agent are fully mixed with each other under the uniform stirring action of the impeller, which increases the reaction time of the agent to the pulp and strengthens the reaction quality of the drug. In this way, the materials can be fully stirred and mixed, and the necessary preparation conditions are made for the next stage of flotation machine production.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

| Category | Specification | Tank size | Effective volume (m3) |

Main shaft speed(r/min) | Motor power(kw) | Dimension (mm) |

Weight (kg) |

|

| Diameter (mm) |

Height (mm) | |||||||

| Agitating tank | XB-10×10 | 1000 | 1000 | 0.58 | 390 | 1.5 | 1130×1130×1521 | 1050 |

| XB-12×12 | 1200 | 1200 | 1.18 | 390 | 2.2 | 1130×1330×1721 | 1160 | |

| XB-15×15 | 1500 | 1500 | 2.2 | 280 | 3.0 | 1750×1640×2190 | 1270 | |

| XB-20×20 | 2000 | 2000 | 5.6 | 210 | 5.5 | 2380×2160×2850 | 1700 | |

| XB-25×25 | 2500 | 2500 | 11.2 | 190 | 7.5 | 2990×2720×3540 | 3500 | |

| XB-30×30 | 3000 | 3000 | 19 | 140 | 18.5 | 4030×3270×3010 | 5200 | |

| XB-35×35 | 3500 | 3500 | 29 | 230 | 30 | 3920×3740×4970 | 6630 | |

| XB-40×40 | 4000 | 4000 | 45 | 210 | 37 | 4520×4320×5570 | 7830 | |

| Lifting type | XBT-10×15 | 1000 | 1500 | 1 | 510 | 2.2 | 1130×1130×2070 | 1250 |

| XBT-15×20 | 1500 | 2000 | 2.9 | 400 | 4 | 1636×1768×2785 | 1677 | |

| XBT-20×20 | 2000 | 2000 | 5.6 | 312 | 11 | 2180×2220×3015 | 3100 | |

| High-efficiency leaching tank | XF-20×20 | 2000 | 2000 | 7.07 | 82.5 | 1.5 | 2032×2032×3595 | 2400 |

| XF-25×30 | 2500 | 3000 | 13.5 | 57.6 | 2.2 | 2532×2532×4152 | 3670 | |

| XF-30×30 | 3000 | 3000 | 22.97 | 50.0 | 2.2 | 3180×3180×4673 | 5340 | |

| XF-35×40 | 3500 | 4000 | 35.6 | 41.0 | 4.0 | 3685×3685×5314 | 7140 | |

| XF-40×45 | 4000 | 4500 | 52.78 | 33.5 | 4.0 | 4185×4185×5814 | 9300 | |

| XF-45×50 | 4500 | 5000 | 74.75 | 33.5 | 5.5 | 4685×4685×6466 | 10500 | |

| XF-50×55 | 5000 | 5500 | 102.1 | 30.6 | 5.5 | 5185×5185×6975 | 12300 | |

| XF-55×60 | 5500 | 6000 | 135.4 | 24.4 | 7.5 | 5670×5670×7569 | 13500 | |

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.