Model: Ø2.5×40m-Ø4.0×60m

Capacity: 40-350TPD

Application: Mainly used for calcining cement clinker

Materials:(different sizes for 120 kinds of stones)

benonite

cement

clay

coals

Applied material: PE250*400 PE600*900 PE-1200×1500 PEX250*1200

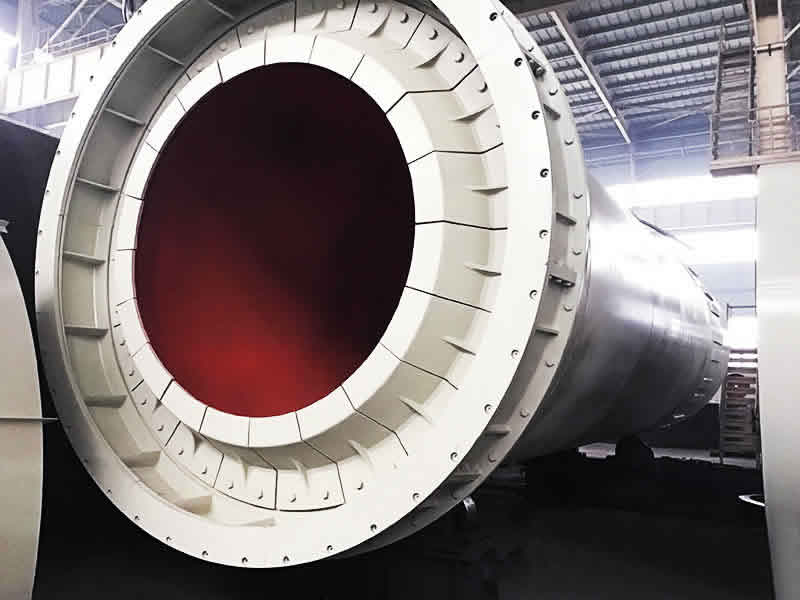

The cement shaft kiln is a kiln with a vertical shape, an all-steel structure with a vertical cylindrical cylinder body, and uses the principle of the material's own weight descending and hot air rising to conduct heat exchange for cement firing. The cement shaft kiln is a cost-effective solution for modern production,it is also a boon for developing countries.

1. Cement shaft kiln has stable and reliable operation, environmental protection and energy saving, and high degree of automation.

2. It can use various low-calorific value converters, blast furnace gas, calcium carbide furnace exhaust gas, etc. as fuel, turning waste into treasure.

3. The steel structure of the kiln body has fewer machined parts and lower processing costs,the installation difficulty is not high, and the refractory masonry difficulty is lower.

The shaft kiln is a cylindrical kiln body. The material is added from the top of the kiln and discharged from the bottom of the kiln after calcination. According to the temperature change and distribution in the shaft kiln, the shaft kiln is divided into three zones from top to bottom: preheating zone, calcining zone, cooling zone;

In the preheating zone, the material is preheated by the heat of the flue gas;

In the calcining zone, the material is calcined with the help of the heat released by the combustion of the fuel;

In the cooling zone, the calcined material exchanges heat with the blown cold air, the material itself is cooled, and the air is heated and enters the calcination zone as combustion-supporting air.

In order to ensure that each section of the material calcination process is carried out fully and completely, the three belts in the shaft kiln should maintain a certain height and strive to be stable.

In the shaft kiln system. The material is powered from top to bottom, and the combustion air is powered from the bottom up. The heat carried by the high-temperature material preheats the combustion air. The process is reasonable and the heat loss is small. The discharge temperature can be controlled within the ambient temperature of +60 °C. The heat can be completely controlled within (600~700)×4.18kj, which belongs to the equipment with high thermal efficiency.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

Technical Parameters Of Vertical Kiln (Mixed Fuel)

| Effective Volume(m3) | Effective Height(m) | Effective SectionDia.(m) | Limestone Size(mm) | Heat Consumption(kJ/kg) | CaO(%) | Activity(ml) |

| 98 | 20 | Ø2.5 | 30~60/40~80 | <4600 | >90 | >300 |

| 141 | 20 | Ø3.0 | 30~60/40~80 | <4600 | >90 | >300 |

| 202 | 21 | Ø3.5 | 30~60/40~80 | <4500 | >90 | >300 |

| 301 | 24 | Ø4.0 | 30~60/40~80 | <4500 | >90 | >300 |

| 397 | 25 | Ø4.5 | 30~60/40~80 | <4400 | >90 | >300 |

| 491 | 25 | Ø5.0 | 30~60/40~80 | <4200 | >90 | >300 |

| 735 | 26 | Ø6.0 | 30~60/40~80 | <4200 | >90 | >300 |

| Remarks: All above data are for reference only. | ||||||

Technical Parameters Of Vertical Lime Kiln (Fuel: Gas)

| Effective Volume(m3) | Effective Height(m) | Effective SectionDia. or L×W(m) | Limestone Size(mm) | Heat Consumption(kJ/kg) | CaO(%) | Activity(mL) |

| 70 | 20 | Ø2.0 | 30~60/40~80 | <4600 | >90 | >300 |

| 80 | 20 | Ø2.5 | 30~60/40~80 | <4600 | >90 | >300 |

| 100 | 20 | Ø2.5 | 30~60/40~80 | <4500 | >90 | >300 |

| 120 | 20 | Ø2.7 | 30~60/40~80 | <4500 | >90 | >300 |

| 140 | 20 | Ø3.0 | 30~60/40~80 | <4400 | >90 | >300 |

| 150 | 21 | Ø3.0 | 30~60/40~80 | <4200 | >90 | >300 |

| 200 | 20 | 2.5×4.5 | 30~60/40~80 | <4200 | >90 | >300 |

| Remarks: Above data is for reference only, and suitable for Vertical Kiln which use low heat fuel. Utilization coefficient of Vertical Kiln which use high heat fuel is higher. | ||||||

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.