Capacity: 0.5-800M2

Feeding Size: <1mm

Application: pharmaceutical, chemical, food and other industries.

Materials: gold ore, copper ore, iron ore, manganese ore

copper ore

gold ores

iron ores

manganese ore

Applied material:

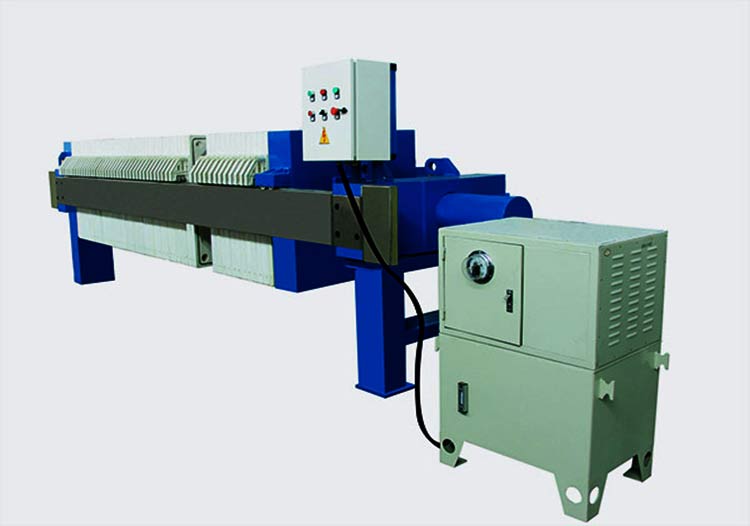

Plate filter press, also known as plate and frame filter press. The plate filter press is an intermittent filter press device used for filtration of various media, with good filter cake effect and low moisture content in the filter cake.

Our company mainly engages in 200, 320, 450, 630, 800, 1000, 1250, 1500, 1600, φ800, φ1000 plate and frame type and box-type filter presses, with a filter area of 0.5㎡-800㎡.

The plate and frame materials are cast iron, reinforced polypropylene, glass fiber polypropylene (temperature resistance 120℃) and stainless steel.

The compaction forms include manual compaction, mechanical compaction, jack compaction, hydraulic compaction, automatic pressure-holding compaction, and computer program-controlled automatic control.

The filtering forms include open flow, undercurrent, open flow washable and two-way cross washing, with various categories and complete models.

Plate filter press is a kind of intermittent operation pressure filter equipment, suitable for solid-liquid separation of various suspensions, with good separation effect, simple structure, convenient operation, safety and reliability, and is widely used in petroleum, chemical industry, ceramics, dyes , pharmaceutical, sugar, food, metallurgy, textile, environmental protection and coal industries.

The flat filter press produced by our company has the following characteristics:

1, The building block structure is adopted, and the structure of each part is reasonable.

2, The connection is simple and different combinations are used to suit the requirements of different users.

3, The whole machine has a high degree of automation, large production capacity, and can operate under high pressure.

4, The liquid content of the filter cake is low, the unit output is high, and the floor area is small.

The plate and the frame are arranged alternately. The two sides of the filter plate are covered with filter cloth, and the plate and the frame are pressed by the pressing device, that is, the filter press chamber is formed between the plate and the frame. There is a small hole in the middle of the upper end of the plate and the frame. After pressing, it becomes a channel. The sludge pressurized to 0.2~0.4MPa enters the filter press chamber through the channel. The surface of the filter plate is engraved with grooves. There are holes for the filtrate to be discharged. Under the pressure, the filtrate is discharged through the filter cloth, along the grooves and holes, and the sludge is dehydrated.

Plate and frame filter presses can withstand higher sludge specific resistance than vacuum filters, which can reduce the consumption of conditioners and allow the use of cheaper reagents (eg FeSO 4·7H 2 O). When the specific resistance of the sludge is 5 × 10 11 to 8 × 10 12 m/kg, it can be directly filtered without pretreatment. The mud cake output and mud cake moisture content of the plate and frame filter press should be determined based on test data or similar operating experience. The moisture content of the mudcake can typically be 75% to 80%.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

| Model | XMZ-230/1500 | XMZ-340/1500 | XMZ500/1500 XXMZ-500/1500 | XMZ-800/1800 | XMZ-1050/2000 | ||||||

| Total area of filter /m2 | 230 | 340 | 500 | 800 | 1050 | ||||||

| Dimensions of filter plate (Length× Width×Height)/mm× mm×mm | 1500×1500×60 | 1500×1500×60(63) | 1800×1800×63(65) | 2000×2000×68 | |||||||

| Number of filter plate / block | 62 | 92 | 132(125) | 138(QT),136( Rubber ) | 150 | ||||||

| Total volume of filter /m ³ | 3.5 | 5.23 | 7.7 | 13 | 18.16 | ||||||

| Maximum filtration pressure /MPa | ≤1(≤1.5) | ≤1.2 | ≤1.5 | ||||||||

| Pressing method of filter plate | Single-cylinder top tight ,P=9-14( Four cylinder synchronous tensioning ) | Single-cylinder top tight | Four cylinder synchronous tensioning | ||||||||

| Processing capability of single cycle /t | 6 | 8 | 12 | 18 | 23 | ||||||

| Total power /kW | 5.5(15.5) | 15 | 22 | ||||||||

| Dimensions of outline | Length /mm | 8100 | 10000 | 12020(13641) | 13250 | 16910 | |||||

| Width× Height /mm×mm | 2620×3487× (2650×4000) | 2920×4000 | |||||||||

| Model | XMZ-230/1500 | XMZ-340/1500 | XMZ500/1500 XXMZ-500/1500 | XMZ-800/1800 | XMZ-1050/2000 | ||||||

| Total area of filter /m2 | 230 | 340 | 500 | 800 | 1050 | ||||||

| Dimensions of filter plate ( Length × Width× Height)/mm× mm×mm | 1500×1500×60 | 1500×1500×60(63) | 1800×1800×63(65) | 2000×2000×68 | |||||||

| Number of filter plate / block | 62 | 92 | 132(125) | 138(QT),136( Rubber ) | 150 | ||||||

| Total volume of filter /m ³ | 3.5 | 5.23 | 7.7 | 13 | 18.16 | ||||||

| Maximum filtration pressure /MPa | ≤1(≤1.5) | ≤1.2 | ≤1.5 | ||||||||

| Pressing method of filter plate | Single-cylinder top tight ,P=9-14( Four cylinder synchronous tensioning ) | Single-cylinder top tight | Four cylinder synchronous tensioning | ||||||||

| Processing capability of single cycle /t | 6 | 8 | 12 | 18 | 23 | ||||||

| Total power /kW | 5.5(15.5) | 15 | 22 | ||||||||

| Dimensions of outline | Length /mm | 8100 | 10000 | 12020(13641) | 13250 | 16910 | |||||

| Width× Height /mm×mm | 2620×3487× (2650×4000) | 2920×4000 | |||||||||

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.