Capacity: 50-2000tpd

Fuel: coal, natural gas etc.

Main Equipment: crusher, dryer, raw mill, pre-heater, rotary dryer, packing machine

Output size(different sizes for 120 kinds of stones)

slag cement

pozzolana cement

portland cement

fly ash cement

Applied material:

want to know the flowchart of cement manufacturing process, we can help you.

leave your whatsapp or email, we sent flowchart to you now

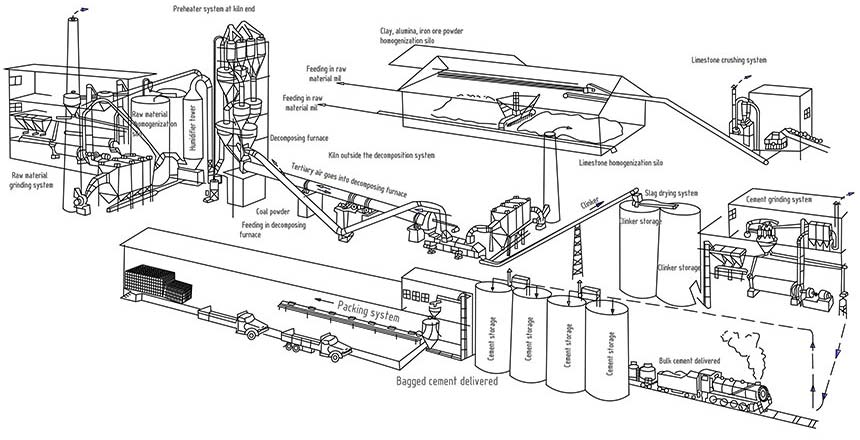

The cement production line is a production line construction project composed of a series of supporting equipment for the production of cement. It is mainly composed of crushing, homogenizing, raw material preparing, drying, preheating decomposition, clinker firing, cooling, grinding, packaging, conveying, environmental protection dust collection and other equipment.

Turui company provides process design, civil construction, complete sets of equipment, installation and commissioning, technical and other services.

In the process of cement production line, 3 tons of materials (including various raw materials, fuels, clinkers, mixtures, and gypsum) are required to be grinded for every 1 ton of Portland cement produced.

According to statistics, the power consumption of dry cement production line grinding operation accounts for more than 60% of the power of the whole plant, of which raw meal grinding accounts for more than 30%, coal grinding accounts for about 3%, and cement grinding accounts for about 40%.

Therefore, reasonable selection of grinding equipment and process flow, optimization of process parameters, correct operation, and control of operation system are of great significance to ensuring product quality and reducing energy consumption.

Heat Consumption: ≤840kcal/kg

Power Consumption: ≤110kwh/t

Water Consumption: 1020m³/d maximum

Cement production uses limestone and clay as the main raw materials, which are crushed, batched, and grinded into raw material by raw mill, and then fed into cement rotary kiln for calcination to become clinker, and then add appropriate amount of gypsum to the clinker, add some mixed materials or additives, and grind it into cement by cement ball mill, and then transported out of the factory by a packaging machine or a bulk machine.

At present, cement plants usually adopt the dry process cement production process, which dry and grind raw materials into raw materials at the same time and feed them into a dry rotary kiln for calcining become clinker. The main advantage of dry production is the low heat consumption.

(1) Raw Material Crushing & Conveying

(2) Raw Material Batching & Grinding

(3) Clinker Calcinations & Cooling

(4) Cement Dosing & Grinding

(5) Cement Packing & Conveying

The main equipment of cement production line includes: cement rotary kiln, preheater, cooler, crusher, raw material grinding mill, cement mill, coal mill, dryer, dust collector, packaging machine, bulk machine, conveyor machine, electrical control, etc.

| No. | Workshop name | Main equipment | Work plan | Quantity |

| 1 | Limestone crushing | Single-Stage Hammer Crusher Feeding size: <600mm Capacity: 120t/h Discharging size: 90% <25mm |

6d/w×7h/d | 1 |

| 2 | Mixed material crushing | High-Efficiency Crusher Feeding size: <215mm Capacity: 50t/h Discharging size: 90% <20mm |

1d/w×7h/d | 2 |

| 3 | Raw material grinding | Ball Mill Feeding size:≤25mm Finished fineness:<R12% @ 80 μ Feeding moisture:≤ 8% Finished moisture:<1% Capacity: 50 t/h |

7d/w×20h/d | 1 |

| 4 | Clinker calcination | Rotary Kiln Heat consumption: ≤950kCal/kg Capacity: 800t/d(33.3t/h) Power: 220kW Fuel: gas |

7d/w×24h/d | 1 |

| 5 | Cement grinding | Cement Mill Feeding size:≤20mm Finished fineness:<R3.5% @ 80 μ Capacity: 45 t/h PC32.5 Power: 1600kw |

7d/w×22h/d | 1 |

| 6 | Cement packing | Rotary Packing Machine Capacity: 100t/h With cement bulk machine |

6d/w×12h/d | 1 |

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.