Model : Φ1500×3000-Φ2500×3900

Capacity : 2-5t/h

Material : Dolomite, Ferrosilicon, Fluorite powder

Output size(different sizes for 120 kinds of stones)

32.5

42.5

52.5

62.5

Applied material:

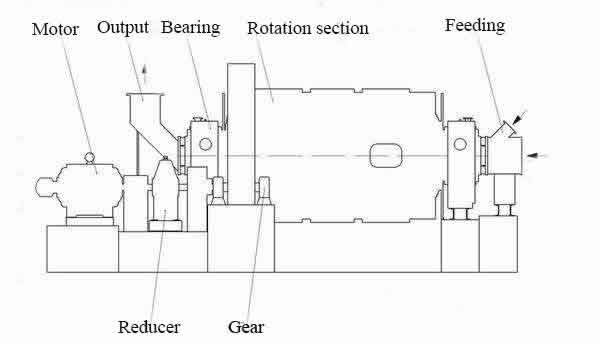

Coal mill is major equipment of cement plant and used for drying and grinding coal. The equipment is mainly consisted of feed device, main bearings, rotating parts, drive device, selling device, high-voltage start-up device and lubrication system. The raw material is fed into mill by feeding equipment. The hot wind enters into the mill from inlet end. As the mill cylinder rotates, the coal and hot air exchange heat in the mill. The coal is crushed and grinded in the mill. When the coal is being grinded, the powder is brought out of the mill by the hot air going through the mill. The products have got the international quality certification of ISO9001:2000 and the European CE certification. The coal mill we make is with reasonable structure, high grinding efficiency and ideal equipment for coal processing.

Air swept coal mill is consisting of feeding device, main bearing, rotating parts, discharging device, high pressure starting device and lubrication system. And the feeding device is consisting of feed pipe, blast pipe and etc.

Coal mill is a skeleton pattern ball mill with horizontal cylindrical turning gear, driving by outer gear and two compartments. The material goes to the first compartment after the spiraling by the quill shaft from the feeding equipment. The compartment has ladder liners or corrugated liners with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first compartment, by monolayer partition panel, the material will enter the second compartment, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to complete the grinding.

1. High grinding efficiency and low energy consumption;

2. Less metal consumption per unit of products;

3. Continuous operation, and large production capacity;

4. Reliable performance, and low maintenance costs;

5. Fine grinding fineness, and uniform size;

6. Simple structure with large drying capacity;

7. Small vibration, low noise, good sealing, no dust spilling, clean environment, which meet the national environmental protection requirements.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

| Spec(mm) | Capacity(t/h) | Rotating Speed(r/min) | Grinding Medium(t) | Motor | Reducer | Weight(t) | ||

| Model | Power(kw) | Model | Speed Ratio | |||||

| Φ1500×3000 | 2~3 | 29.2 | 6.5 | JR125-8 | 95 | ZD35-6 | 3.55 | 19.5 |

| Φ1700×2500 | 3~5 | 24.32 | 8 | JR116-6 | 95 | ZD40-8 | 4.481 | 23.1 |

| Φ2200×3000 | 5~6 | 22 | 13 | JR147-8 | 200 | ZD50-9 | 5 | 32.8 |

| Φ2400×4750 | 2~3 | 20.4 | 22 | YR4001-8 | 280 | ZD60-8 | 4.481 | 48.9 |

| Φ2500×3900 | 3~5 | 20.89 | 24 | YR5002-8 | 315 | ZD60-8 | 4.481 | 47 |

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.