Capacity: 50,000-200,000(t/a)

Materials: bauxite, manganese powder and additives

Main equipment: crusher, grinding ball mill, powder separator, granulator, rotary kiln, cooler, rotary screen, packing machine.

Output size(different sizes for 120 kinds of stones)

slag cement

pozzolana cement

portland cement

fly ash cement

Applied material:

Our company is a leading manufacturer of complete equipment for fracturing proppants production line. We can provide the whole service of design, equipment and spare parts supply, investment consultation, installation and operation training.

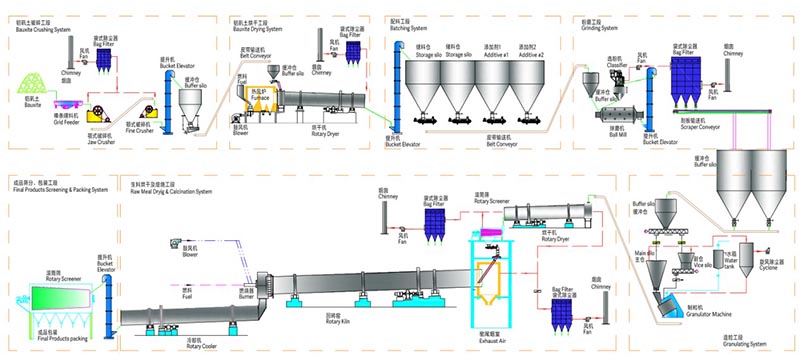

The oil fracturing proppant production line is completely designed according to the properties and production requirements of oil fracturing ceramsite sand. The production and preparation of ceramsite sand is mainly carried out by taking various steps. There are several key processes in the whole process flow: crushing stage, fine crushing stage, screening stage and calcination stage, which are indispensable. The oil fracturing proppant production line is carefully designed in full consideration of the needs of users, so that each equipment can play its role. All equipment has an indispensable role in the production line. The configuration of the entire production line is scientific and reasonable, and the investment is ideal. All equipment model and parameters on the oil fracturing proppant production line have been researched and formulated, so that all equipment cooperates tacitly, the production line is generally designed reasonably and the production process is smooth. The whole process design of the production line is mature, the produced proppant has high economic benefits, the finished product is widely sold in the market, and the application field is also very wide, which improves the economic value of material and develops its potential value.

Bauxite of 300-500mm is crushed and sent to the dryer for drying. And all pass through the batching station with manganese powder and additives, etc., and enter to the grinding system with classifier to produce 400mesh raw meal powder. With the new type of granulator, after adding water, the raw meal powder is made into pellets with qualified particle size. The pellets enter the rotary dryer at the kiln end, by using the waste heat of the exhaust gas at the kiln end, the moisture of the pellets is reduced; and then enter the rotary kiln for calcination after screening. The calcined proppant is cooled by a single-cylinder rotary cooler and then sieved through a rotary screen. The qualified pellets with different particle sizes are packaged separately and shipped out, and the unqualified pellets are returned to the grinding system.

1. Reasonable layout, smooth process and high degree of automation;

2. Mechanized joint control operation, and low labor intensity;

3. Real-time monitoring of calcining parameters, and quality sintering products;

4. Good energy consumption ratio and low operating cost

The oil fracturing proppant production line can meet the production process requirements of oil fracturing proppant products. It can produce conventional products with a crush resistance of 53Mpa and 69Mpa, and can produce products with a crush resistance of 86MPa and 102Mpa, with a particle size of 0.2-0.9mm, which fully meets the requirements of the Q/SH0051-2007 standard.

1. Crushing and Screening System: The mined bauxite is generally about 300~500mm in size and contains a small amount of water. Generally, a two-stage crushing system composed of jaw crusher and hammer crusher is used, and the crushed particle size is controlled to be less than 8mm. After entering the factory, the bauxite can be stacked separately according to different grades and use it according to the indicator. Manganese (Mn) element is usually added in the process of producing proppant to lower the sintering temperature and dye the product dark. At present, most domestic manufacturers use low-grade (~50%) manganese ore or manganese ash as the source of manganese.

2. Batching system: several materials such as bauxite, manganese powder, and return material are transported to their respective silos. A speed-adjusting belt scale is installed under the production process silo, to realize automatic batching and measurement of materials.

3. Grinding System: in grinding process, the main equipment is ball mill and high-efficiency powder separator, forming a close-circuit grinding system. The required raw meal powder size is lower than 300mesh to meet the demands of granulators.

4. Granulating System: Raw meal powders are stored in the silo. Usually there are two or three silos, which can be discharged individually or with multiple banks. The raw meal powder is fed into a small hopper, and a screw metering device or a speed-adjusting belt weighing device is installed under the hopper to measure the amount of raw meal. The raw meal enters the granulator. At the same time, the flow meter can be used to measure the amount of water, and the water is sprayed into the granulator by the pipeline pump. During the rotation of granulator, pellets of various particle sizes can be made. After the pellets are discharged from granulator, they are sent to the screening device by the belt conveyor, the qualified ones enter the rotary kiln, and the oversized are returned to the raw material grinding process. According to the output capacity of kilns, different numbers of granulators can be equipped. This granulating system has a high degree of automation and a continuous process. After being equipped with a bag filter, the dust can reach the standard and the working environment can be purified.

5. Rotary Kiln Calcination Sytem: the pellets enter the rotary kiln with a certain inclination for calcination. With the rotation of rotary kiln, the pellets roll toward the kiln head, and at the same time, the pulverized coal is injected into the kiln from the kiln head for combustion, and the pellets are calcined in the rotary kiln to the high strength proppant.

6. Pulverized coal preparation system: (when the fule is coal) the preparation of pulverized coal consists of raw coal storage and transportation system, grinding system, powder collecting system, electrical and instrument automation system. The air-swept coal mill hot air inlet pipe and coal air outlet pipe are provided with explosion relief valve and nitrogen protection interface to protect equipment and system safety. The powder separator equipment adopts the frequency conversion motor to regulate the speed. By adjusting the frequency converter, the powder fineness of the powder separator can be controlled remotely.

7. Products Cooling System: the cooling of proppant generally adopts a rotary cooler, which is simple and reliable in operation. The secondary air of the cooler is completely fed into the kiln. With the use of multi-channel burners, a lot of energy consumption can be saved. The temperature of the proppant coming out of the cooler is very low and can be picked up by hand.

8. Finished Products Screening System: the proppant from the cooler can be directly transported to the multi-stage vibrating screen, and divided into multiple particle size grades as required.

9. Packing: proppants after screening will be transported to different hoppers, the hoppers are connected with packing machine; finished products will be packed and transferred to storage house to prepare for delivery.

All dust points in the process need match with dust collector to purification the exhaust air. Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.