Model : Max feed size: 25mm

Capacity : 0.65--2T/H

Material : Research Institutes, Universities, Enterprises Investment

Output size(different sizes for 120 kinds of stones)

32.5

42.5

52.5

62.5

Applied material:

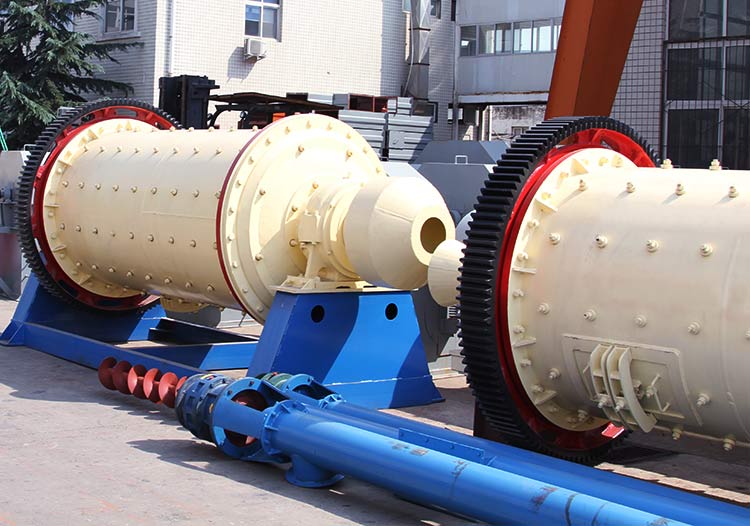

Lab scale ball mill (Laboratory Ball Mill, Small Scale Ball Mill) is used for making test of grinding materials like ores, chemicals, ceramic materials etc, with capacity from a few kgs to about 1000 kgs. Actually Laboratory ball mill can take care of any pulverizing, milling or grinding job that you can give it. Its multifunction design allows it to handle wet or dry, brittle or fibrous materials. It is a flexible, reliable, compact design, best for laboratory and research use. According to clients' request, the laboratory ball mill can be produced by stainless steel, motor 3 phase or single phase.

Turui Mini ball mill is a small powder and superfine powder milling equipment employed to grind minerals such as calcite, cretaceous, caoline, limestone, bentonite, talcum, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite clay, rectorite, diatomite, barite and so on. The particles could be milled to 0.074mm, meeting the different requirements.

The small ball mill is a horizontal rotary cylindrical equipment driven by gears outside. When the small ball mill works, the raw materials are evenly fed from the feeding port through the hollow shaft into the first chamber with stepped lining plates or wavy lining plates of various steel balls in different sizes, and the centrifugal force brings the steel balls to a certain height and then the balls fall down to impact, crush and grind the materials. After leaving the first chamber, the qualified particles enter through a single dividing plate into the second chamber with flat plates and steel balls. The materials are further grinded in this chamber where the final qualified particles and powders are discharged from the opening port.

Small ball mill is mainly composed of feeding part, discharging part, cylinder part and transmission part. The hollow shaft is made of casting steel with changeable inner lining plate. The big rotary gear is processed by hobbing castings, and high wear-resistant lining plates are adopt inside the cylinder body.

1. Adopt ultra-thick steel plate; strong cylinder structure design.

2. High manganese steel lining plate with good wear resistant and long service life.

3. Mini ball mill base seat is made of high quality Babbitt metal ensuring the stable operation of the whole machine.

4. Pinion gear and bull gears with high strength and high precision, high quality reduction gear and motor. Professional design and manufacturing process, on time delivery, fast shipping.

5. The Mill Ball Mills work stably and reliably, and can be divided into dry Ball Mills and wet Ball Mills according to the materials to be grinded and the discharging styles.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

| Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Motor Model | Motor Power (kw) | Motor RPM (r.p.m) | Length (mm) | Width (mm) | Height (mm) | Processing Capacity (t/h) | Maximum Ball Volume (t) | weight (kg) |

| MQG0909 | 900 | 900 | Y225S-8 | 17 | 730 | 3120 | 2210 | 2020 | 0.16~0.8 | 0.96 | 4620 |

| MQG0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 3620 | 2230 | 2020 | 0.33~1.6 | 1.92 | 5340 |

| MQG1212 | 1200 | 1200 | Y250M-8 | 30 | 730 | 5100 | 2800 | 2500 | 0.16~2.6 | 2.4 | 11438 |

| MQG1224 | 1200 | 2400 | Y315S-8 | 55 | 730 | 6500 | 2800 | 2500 | 0.26~6.15 | 4.8 | 13200 |

| MQG1515 | 1500 | 1500 | JR115-8 | 60 | 725 | 5650 | 3260 | 2700 | 1~3.6 | 4 | 13700 |

| MQG1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7480 | 3300 | 2700 | 2~6.8 | 8 | 18690 |

| MGG2122 | 2100 | 2200 | JR128-8 | 155 | 730 | 8070 | 4839 | 3794 | 5~29 | 16 | 47400 |

| MQG2136 | 2100 | 3000 | JR148-8 | 240 | 735 | 8640 | 4839 | 3794 | 8~40 | 21 | 50600 |

| MQG3045 | 3000 | 4500 | TDMK630-36 | 630 | 167 | _ | _ | _ | 20~45 | 55 | 135000 |

| MQG3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | _ | _ | _ | 75~100 | 68 | 155000 |

| MQG3655 | 3600 | 5500 | TDMK1250-40 | 1250 | 150 | _ | _ | _ | 120~190 | 97 | 205000 |

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.