Model: Φ1.6x32--Φ4.0x60(m)

Capacity: 2-20(t/h)

Material: bauxite

Materials:(different sizes for 120 kinds of stones)

benonite

cement

clay

coals

Applied material:

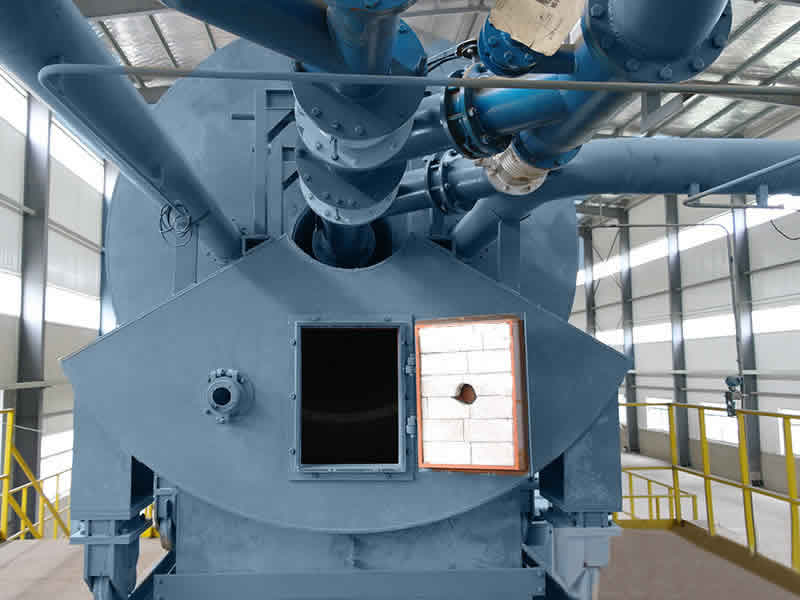

Oil fracturing proppant rotary kiln is currently the most ideal calcining equipment for oil proppant processing, and it is also one of the most critical processes. Its main advantages are: large capacity, easy to control, strong operability, suitable for various specifications ceramsite sand callcination. In view of the specificity of ceramsite sand, The rotary kiln developed and produced by our company, combined with the deficiencies in actual production, continuously improves the product, making the product more and more perfect, thus effectively ensuring the calcining quality of the petroleum proppant.

Oil fracturing proppant, commonly known as petroleum proppant, also known as ceramsite sand, is a ceramic particle product with high fracturing strength. It is mainly used for downhole support in oil fields to increase oil and gas production, and it is an environmentally friendly product. This product is made of high-quality bauxite, coal and other raw materials, and is sintered with ceramics. It is a substitute for medium and low strength proppants such as natural quartz sand, glass balls, and metal balls. It has a good effect on increasing oil and natural gas production.

The kiln body of the rotary kiln has an inclination of 3%-4% (sine) with the horizontal plane. The whole kiln body is supported on the corresponding supporting roller device through two tyres, and passes through the thrust rollers at the kiln end in the axial direction of the kiln body, preventing it from moving up and down. the transmission process is that the variable frequency motor drives the pinion to rotate through the reducer and its coupling, the pinion meshes with the large ring gear fixed in the middle of the kiln cylinder, and finally the large ring gear drives the cylinder to rotate.

The fuel is injected into the kiln by the gas or pulverized coal from the kiln head through the burner for combustion. The heat is transferred to the material by the radiation of the flame, the convection of the hot gas, the conduction of the kiln brick, etc., and becomes finished products after calcination.

Materials are fed from the high end of the kiln shell (kiln tail part). Due to the inclination and slow rotation of the cylinder, the material will produce a comprehensive movement of rolling along the circumference and moving in the axial direction, and will be continuously conveyed to the lower end of the kiln cylinder (the kiln head part). The material is sent into the kiln from the kiln head for combustion, and the material meets the high-temperature airflow during the flow process, and is continuously heated to complete the physical and chemical reaction. The calcined materials are discharged from the kiln head and enter the next process.

1. Simple structure, high unit volume, long kiln life, high operation rate, stable operation, high heat transfer efficiency, low heat consumption, etc.;

2. Automatic temperature control, over-temperature alarm, utilization of waste heat from secondary air intake, and long service life of kiln lining;

3. With advanced kiln head and kiln tail sealing technology and devices, it has features of stable operation and high output.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia, Tanzania, Peru, Mexico.

| Model | Capacity (t/h) |

Rotation Speed (rpm) |

Support Quantity | Gear Box | Motor Model |

Power (kw) |

| Ø1.6×32m | 0.8-1.5 | 0.58-2.85 | 3 Groups | ZQ75-50 | YCTZ50-4A | 18.5 |

| Ø1.9×39m | 1.6-4 | 0.53-1.59 | 3 Groups | ZQ125-7 | YCT315-4A | 37 |

| Ø2.2×45m | 2.5-8 | 0.214-1.64 | 3 Groups | Main ZS125-5 Auxiliary ZQ40-40 |

Main YCT315-4B AuxiliaryY112M-4 |

45 4 |

| Ø2.5×50m | 7.5-15 | 0.62-1.5 | 3 Groups | Main ZS165-5 Auxiliary ZS50-1 |

Main YCT355-4A Auxiliary Y160M-6 |

55 7.5 |

| Ø2.8×55m | 8.5-17 | 0.62-1.5 | 3 Groups | Main ZS165-6 Auxiliary ZS50-1 |

Main YCT355-4B Auxiliary Y160L-6 |

75 11 |

| Ø3×60m | 17-20 | 0.5-1.5 | 4 Groups | Main ZS165-3 Auxiliary ZS50-1 |

Main ZSN-280-11B Auxiliary Y160L-6 |

125 11 |

| Ø3.2×50m | 20-50 | 0.788-3.938 | 3 Groups | Main NZS995-28VBR Auxiliary ZL50-9-2 |

Main ZSN4-280-21B Auxiliary Y180L-6 |

160 15 |

| Ø3.6×55m | 30-92 | 0.39-3.9 | 3 Groups | Main ZSY500-40 Auxiliary ZSY180-31.5 |

Main ZSN-315-072 Auxiliary Y180L-4 |

250 22 |

| Ø4.0×60m | 32-105 | 0.39-3.9 | 3 Groups | Main ZSY630-35.5 Auxiliary ZL65-16 |

Main ZSN4-355-092 Auxiliary Y200L-4 |

315 30 |

Company Industry Experience(40 Years)

Company Industry Experience(40 Years)

Leading Manufacturer and Export Base of Crushing and Mining Machinery

Response Time <24h

Response Time <24h  Factory Price 100%

Factory Price 100%  Online Service 24h

Online Service 24hPlease feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.

Copyright © 2012-2022 Henan Turui Machinery Co., Ltd. All Rights Reserved.